Read the full series on The Future of Production Planning:

Part 1

Part 2

Part 3

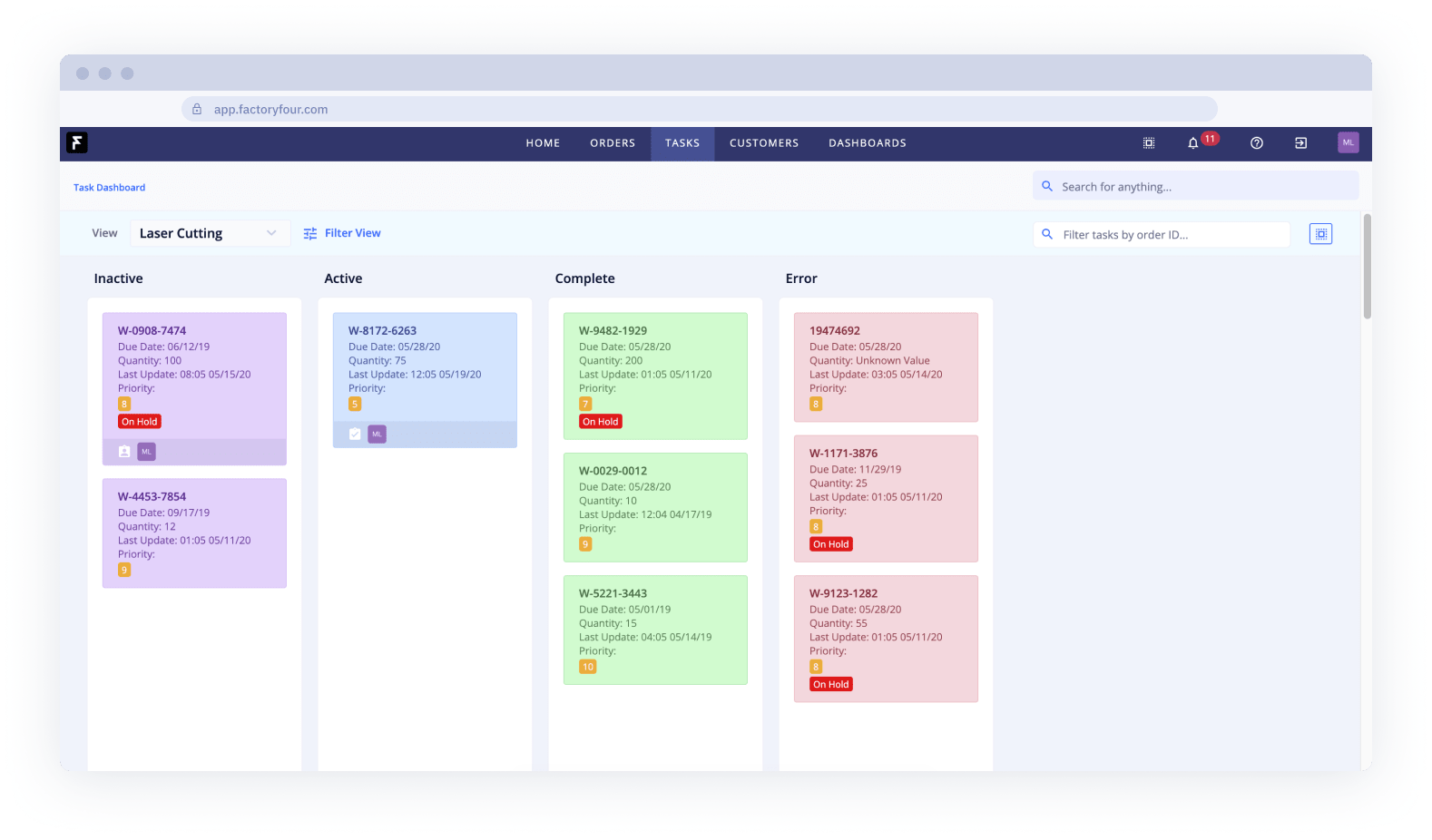

Since our inception, FactoryFour has been built on agile principles to promote the optimization of productivity and human-resource utilization. We’ve always believed that showing operators only work that is available is the best way to keep contributors focused and productive. To that end, the first interface we ever created was the Task Board, a modified Kanban board that leverages task dependencies to show only tasks that are ready for work. The Task Board has always been the best way for contributors to see and log their work. We want to continue to push it forward.

The FactoryFour Production Planning App will be the latest, and perhaps the most significant, improvement to the Task Board functionality. In this post, the second of our The Future of Production Planning series, we will review the current state of the Task Board and why this is a backbone to executing the production plan. After all, a plan is only ever as good as its execution.

FactoryFour Workflows

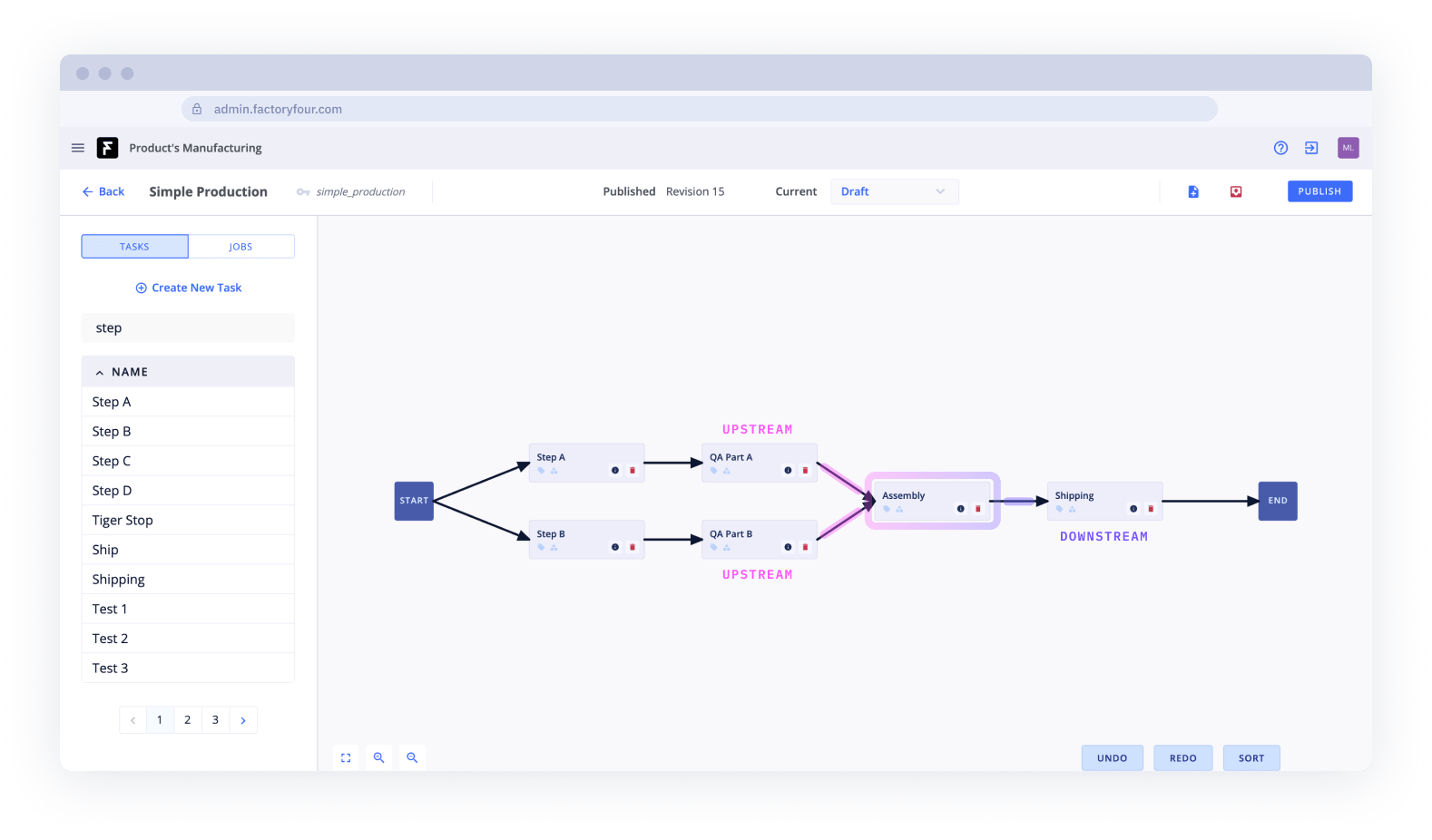

If the Task Board was the interface that FactoryFour was built around, then our workflow data structure was the decision we made on Day 1 that enabled it all. FactoryFour workflows are directed, acyclic graphs of the tasks required to produce a desired output, whether that be a finished good, a sub-component, or a validated product design.

What does that look like? Each workflow has a series of tasks connected by arrows from “Start” to “End.” Each arrow represents a task dependency, meaning the downstream task depends on the completion of the upstream task. All together, dependencies inform the order in which tasks must be completed.

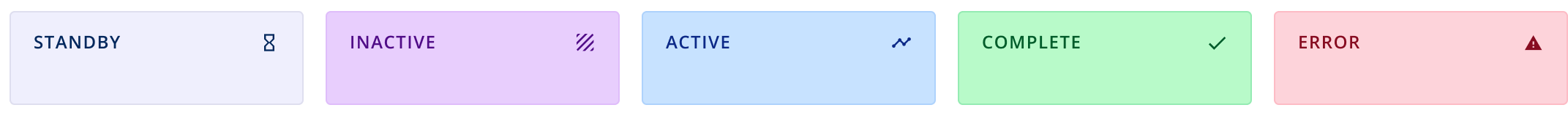

Why is it significant? This structure allows for the enforcement of processes and easily accommodates workflows with complex parallelized dependencies. When a workflow is created, all tasks are set to standby status. Once all task dependencies have been met, the task status changes to inactive, indicating that it’s ready for work. This allows users on the floor to filter for—and select to complete—inactive tasks, while disregarding standby tasks.

Task Statuses:

- Standby – Task not ready, all task dependencies have not been completed

- Inactive – Task ready for work, no current activity

- Active – Current activity ongoing by at least one resource

- Complete – Task completed, the next tasks are ready to be activated

- Error – Unexpected problem requiring additional resources

Task Board Views

Filtering by task status is only the first step; at any given time a contributor on the floor is only concerned with a subset of all work going through the factory. Rather than working off of a master task board with all tasks for all orders currently going through the factory, they need a view of only tasks relevant to them. In FactoryFour, users apply and save relevant filters as a view to easily access again. Typically a user will have a separate view for each work center or role they may perform.

Now that every user has access to relevant tasks that are ready for work, in what order should they be completed?

Business-Specific Task Sorting

Our goal for the task board is for every user to confidently pick the task at the top of their view based on business priorities. The problem is every business operates and prioritizes different criteria - so we’ve created the ability for FactoryFour admins to modify the default task sorting algorithm to match their needs or even create multiple sorting algorithms when different work centers or users need to prioritize work differently.

The FactoryFour default sorting method is first-in, first-out (FIFO) to minimize queue time for any one task. This works really well for standard orders, but what happens when a hot order comes in? Sorting first by a priority tag, for example, may be desired. There are limitless ways to build a sorting algorithm –available sorting criteria include:

- FIFO – first-in, first-out based on when each task’s dependencies were met (default)

- Task Assignment – when using the task assignment feature this will bring tasks assigned to the user accessing the view to the top

- Task Tags – tags are flexible data structures that allow for categorization in FactoryFour that can be used to sort by traits like required skill level or an attribute that may reduce changeovers

- Total Time Checked-In – for longer tasks that span a break or even a shift it may help to sort by total time to ensure that tasks that are closest to completion are completed first to minimize WIP inventory

- Order Dates – standard order dates like submission date, requested delivery date and due date are built into the standard order information on FactoryFour

- Order Attributes – datapoints and tags are two highly flexible data structures used to add context to an order that can be used to sort by order priority or additional milestone dates

What makes this feature so powerful is that every time a change is made to a task or the order a task belongs to, the algorithm re-computes the sort for the entire board in real time. When a requested date changes or a high priority order comes in, the production planner doesn’t need to scramble to update the schedule and notify all of the relevant work centers. Instead, the tasks in the new or modified order will float higher up the list automatically and will be worked on in alignment with business priorities.

What’s Missing?

This works very well for manufacturers that process orders first-in, first-out but is difficult to use for higher mix manufacturers that must schedule production. Right now we are forcing these manufacturers to leverage datapoints to manually enter milestone dates to approximate scheduling and require sorting by those dates. When production orders are vastly different in man-hours and/or duration sorting only by production milestones isn’t sufficient. Simply put, every user should be able to pick the next task at the top of the backlog and begin working on it with confidence. Our customers need more sorting criteria to realize the full value of their task boards.

FactoryFour Production Planning

The only way to provide the criteria required to execute on a schedule was to build an integrated planning tool. We heard the complaints from production planners – too much to do, too little time, and no adequate tools. The last thing we wanted to do was give them another tedious tool that didn’t meet their needs. With the benefit of our existing platform, it was clear that we could provide a powerful, yet light-weight planning solution that a standalone planning system could never offer.

In short, by leveraging our existing workflow and task structures we can capture more detailed capacity requirements. Introducing a new milestone feature to workflows will allow production planners to macro-tune the workflow plan against capacity constraints, and leave the micro-tuning of planning to the sorting algorithm. All the while, contributors can continue to use their personalized task board views as their primary interface to see and log their work.

Stay tuned for the next post of the series where we’ll be formally introducing the FactoryFour Production Planning application and detailing new features and other supporting functionality!

Did you miss the first post? We explored the struggles of production planning today and made the case for a new, less time-consuming approach. The key is to provide a system that is more tolerant of unscheduled delays to avoid redrafting the entire production schedule anytime there is a change. Check it out →

Want to be among the first to demo the FactoryFour Production Planning App? Reach out to one of our experts here or book a demo today.